Thin-film solar panels are increasingly used in commercial and utility-scale installations, especially where weight, flexibility, and large surface coverage matter. Unlike traditional crystalline silicon panels, thin-film panels use different materials and manufacturing methods that change how they must be handled at the end of life.

Improper disposal creates real environmental, safety, and compliance risks. These panels are not just glass and metal—they contain regulated substances that don’t belong in landfills or scrap piles.

This guide explains why thin-film solar panel recycling matters, what’s inside these panels, and what happens if they’re not recycled correctly.

What Are Thin-Film Solar Panels?

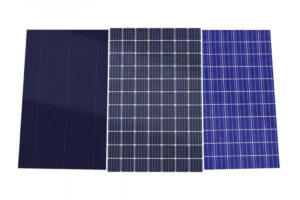

How Thin-Film Panels Differ From Traditional Solar Panels

Thin-film panels are built differently from crystalline silicon panels. They’re typically lighter, thinner, and lower profile, which makes them easier to install across large commercial rooftops and utility-scale solar farms.

They’re often chosen for wide-area coverage rather than peak efficiency. Because of their construction and materials, thin-film panels generally have a shorter lifespan than many crystalline silicon systems, which means they reach the end of life sooner and require proper recycling earlier.

Common Types of Thin-Film Solar Panels

There are several types of thin-film solar panels in use today, each with its own material makeup:

- Cadmium Telluride (CdTe): Common in large-scale solar farms and commercial projects

- Copper Indium Gallium Selenide (CIGS): Used where flexibility and lightweight design are needed

- Amorphous Silicon (a-Si): Often found in specialty or low-power applications

Each type requires controlled handling when decommissioned.

What’s Inside a Thin-Film Solar Panel?

Core Materials and Components

Thin-film solar panels are layered systems made up of multiple materials bonded together, including:

- Glass substrates that form the panel structure

- Ultra-thin semiconductor layers that generate electricity

- Metal framing and backing materials

- Electrical wiring, connectors, and junction boxes

While some of these materials are reusable, they must be separated correctly to avoid contamination.

Regulated and Hazardous Materials

Thin-film panels also contain substances that trigger additional disposal requirements:

- Cadmium compounds are found in CdTe panels

- Selenium and indium are used in CIGS technology

- Trace heavy metals present in certain coatings and layers

These materials require controlled handling and should never be released into the environment.

Why Thin-Film Solar Panels Should Never Go to a Landfill

Environmental Risks

When thin-film solar panels are landfilled, toxic materials can slowly leach into soil and groundwater. Glass and metals do not biodegrade, and once protective layers break down, contaminants migrate outward over time.

Landfills are not designed to permanently contain these substances, especially over decades. Read our complete guide on the effects of electronics in landfills.

Human Health Concerns

Cadmium exposure has been linked to kidney damage, lung issues, and bone deterioration. Improper handling of thin-film panels increases risk to waste workers, transport crews, and communities near disposal sites.

Once contamination occurs, cleanup is difficult, expensive, and often incomplete.

Regulatory and Liability Issues

Thin-film solar panels qualify as regulated electronic waste. Improper disposal may violate environmental laws at the state or federal level.

Responsibility does not disappear once panels leave your site. Generator responsibility typically remains with the owner until proper recycling is completed, creating long-term liability if panels are mishandled downstream.

What Happens When Thin-Film Solar Panels Are Recycled

Step-by-Step Recycling Process

Thin-film solar panel recycling follows a controlled, multi-stage process designed to protect people and the environment.

- Collection and transportation: Panels are safely removed from rooftops, solar farms, or storage areas and transported using appropriate handling methods.

- Panel assessment and sorting: Panels are evaluated by type (CdTe, CIGS, a-Si) to determine the correct processing pathway.

- Separation of materials: Glass, metal framing, wiring, and semiconductor layers are carefully separated.

- Recovery of reusable materials: Glass, aluminum, and other metals are routed back into manufacturing streams where feasible.

- Proper handling of hazardous components: Regulated materials are isolated and managed through controlled recycling channels to prevent environmental release.

Environmental Benefits of Proper Recycling

Recycling thin-film solar panels delivers measurable environmental protection:

- Prevents toxic materials from leaching into soil and groundwater

- Reduces the need for raw material extraction and mining

- Keeps regulated substances out of landfills and uncontrolled disposal streams

When Should Thin-Film Solar Panels Be Recycled?

End-of-Life and Performance Decline

Most thin-film solar panels have a typical lifespan of 15–25 years. As panels age, efficiency declines, and performance becomes inconsistent, making continued operation less practical.

Recycling atthe end of life ensures materials are handled responsibly before degradation leads to environmental risk.

Recycling During Upgrades or Decommissioning

Thin-film panels are often recycled earlier due to operational changes, including:

- Commercial reroofing or building renovations

- Solar farm repowering and technology upgrades

- Equipment failure or system redesign

Recycling during these transitions prevents panels from being stockpiled or improperly discarded.

Thin-Film Solar Panel Recycling for Businesses and Institutions

Who Commonly Recycles Thin-Film Panels

Thin-film solar panel recycling is most common among:

- Solar developers and EPC firms

- Commercial building owners and property managers

- Utilities and municipal energy programs

- Schools, universities, and institutional campuses

These organizations often manage large volumes of panels and require scalable recycling solutions.

Business Recycling Benefits

Professional solar panel recycling services provide clear advantages:

- Scalable pickup and logistics for large projects

- Reduced compliance and environmental risk

- Clear accountability for end-of-life solar equipment

Common Mistakes to Avoid With Thin-Film Solar Panels

Certain assumptions lead to improper disposal and long-term risk. Common mistakes include:

- Sending panels to landfills

- Using unlicensed scrap haulers

- Stockpiling decommissioned panels on-site

- Assuming thin-film panels are “less hazardous” than other solar technologies

Each of these increases environmental exposure and potential liability.

Frequently Asked Questions About Thin-Film Solar Panel Recycling

Are thin-film solar panels recyclable?

Yes. Thin-film solar panels are recyclable and should be processed through a licensed recycler due to regulated materials and complex construction.

Are thin-film panels more hazardous than other panels?

They can be, depending on panel type. Some thin-film panels contain materials that require stricter handling than standard crystalline silicon panels.

Can cadmium-based panels be recycled safely?

Yes. Cadmium-based panels can be recycled safely when handled through controlled, licensed recycling processes.

Do thin-film panels require special handling?

Yes. Thin-film panels require specialized handling to safely manage semiconductor layers and regulated substances.

Can large commercial quantities be recycled at once?

Yes. Licensed recyclers can manage bulk recycling for solar farms, commercial rooftops, and institutional projects.

Conclusion: Recycling Thin-Film Solar Panels Is the Responsible Choice

Thin-film solar panels contain regulated and reusable materials that demand proper end-of-life handling. Improper disposal creates environmental, health, and legal risks that grow over time. Responsible recycling protects people, property, and ecosystems while supporting long-term sustainability.

Recycle Thin-Film Solar Panels the Right Way

Contact a solar panel recycling company to recycle thin-film solar panels safely, compliantly, and responsibly.