What are thin-film solar panels made of? They’re built from ultra-thin photovoltaic coatings layered onto a base material, instead of using thick silicon wafers like traditional panels. That material makeup matters because it affects how the panel performs in heat and low light, how durable it is, and how it needs to be handled and recycled at the end of life.

If you’re replacing or decommissioning thin-film modules, EACR Inc. can help your organization recycle solar panels responsibly and document the process for compliance.

Quick Answer

Thin-film solar panels are layered stacks built on a substrate (glass, metal, or plastic). They include a thin photovoltaic absorber (the power-making layer), conductive layers that move electricity, and protective encapsulation that seals everything from moisture, UV, and physical damage.

The Core Layer Stack

Think of a thin-film module like a “sandwich” of functional layers. Here’s the typical stack, top to bottom.

Front Protective Layer

This is usually tempered glass or a durable polymer top sheet.

What it does: It’s the panel’s shield protecting against impacts, blocking moisture intrusion, and resisting UV exposure so the internal layers don’t degrade as quickly.

Encapsulant and Sealants

Most panels use EVA-like encapsulants, plus edge seals and barrier films to lock everything in place.

What it does: This layer controls moisture, provides electrical insulation, and helps prevent delamination (when layers start separating over time).

Transparent Conductive Layer (Front Electrode)

This is a transparent conductor, often described as a TCO-type layer (transparent conductive oxide).

What it does: It allows light to pass through to the active material while also carrying current across the surface so electricity can be collected efficiently.

The Photovoltaic Absorber Layer

This is the “active” semiconductor coating that converts sunlight into electricity.

What it does: It absorbs photons, frees electrons, and creates usable electrical current. This is also where thin-film technology varies most common absorber types include amorphous silicon (a-Si), cadmium telluride (CdTe), and copper indium gallium selenide (CIGS).

Back Contact (Rear Electrode)

This is typically made from conductive metals or metal films designed to collect and move charge.

What it does: It completes the electrical circuit and helps pull charge carriers out of the absorber layer so the panel can deliver power to the junction box and inverter.

Substrate (The Base Material)

Thin-film layers get deposited onto a glass substrate, metal foil, or a flexible polymer base.

How substrate choice changes the panel:

- Glass usually means a more rigid module with strong protection.

- Metal foil can support thin, lightweight designs and certain flexible formats.

- Flexible polymers enable bendable or lightweight applications where rigid panels don’t fit—like curved surfaces or certain building-integrated uses.

The Main Thin-Film Materials

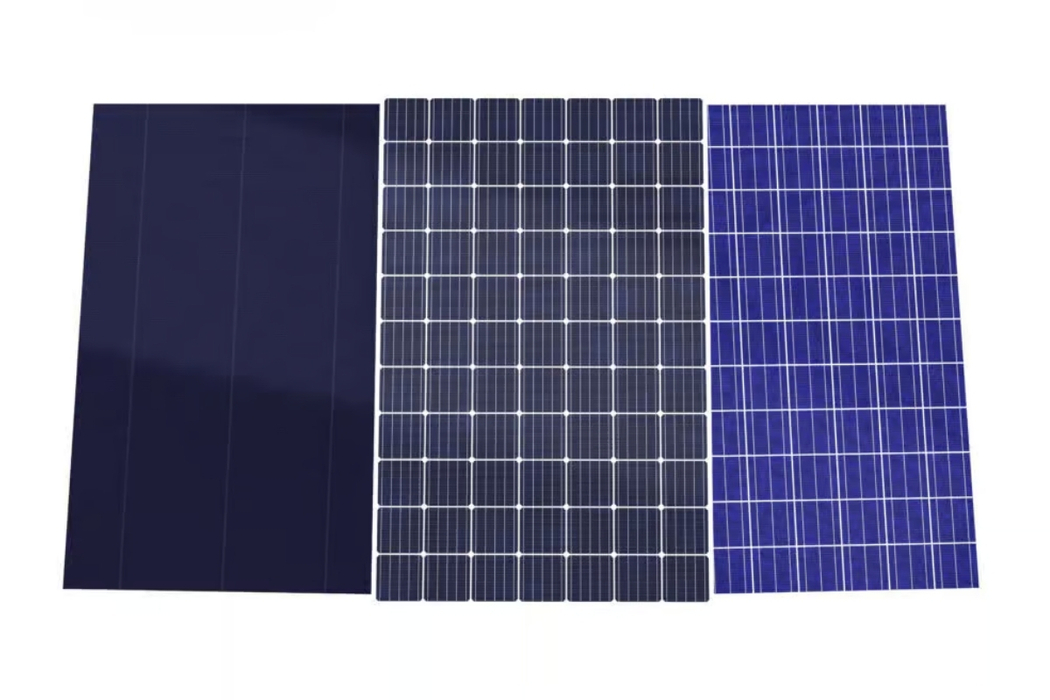

Thin-film solar isn’t one single material. It’s a category of panels that use different ultra-thin absorber layers, and that chemistry drives performance, lifespan expectations, and how recycling should be handled.

Amorphous Silicon (a-Si)

What it’s made of: a non-crystalline silicon coating laid down in a very thin layer.

Why it matters: a-Si is one of the more established thin-film options, but it typically runs lower efficiency than other technologies. The upside is that it can be manufactured in flexible formats, and it has a long track record in certain use cases.

Cadmium Telluride (CdTe)

What it’s made of: a cadmium + tellurium compound absorber layer (CdTe).

Practical considerations:

- Strong light absorption means it can perform well without needing thick material.

- Cadmium content is the big deal here. That doesn’t mean the panel is automatically “unsafe,” but it does mean you should treat end-of-life handling seriously and recycle through a qualified provider.

Copper Indium Gallium Selenide (CIGS)

What it’s made of: layered absorber materials made from copper, indium, gallium, and selenium.

Why it matters: CIGS is known for strong low-light performance and favorable temperature behavior, and it can be produced in flexible formats depending on the substrate. The tradeoff is that the material mix can make recycling and recovery more complex than basic glass-and-metal products.

Organic Photovoltaics (OPV) and Emerging Thin-Film Types

What it’s made of: organic semiconducting layers, often applied using printing-style processes.

Where they show up: OPV and other emerging thin-film tech tend to appear in specialty applications—lightweight, design-driven, or flexible surfaces where traditional rigid panels don’t make sense.

What Else is Inside a Thin-Film Solar Panel?

Even though the PV layers get the attention, thin-film modules also contain “standard solar hardware” that affects transport, teardown, and recycling streams.

Wiring, Junction Box, and Connectors

You’ll typically see copper wiring, polymer housings, and electronics inside the junction box, plus connectors and cable assemblies.

Why it matters: these components often go into different processing streams than the glass and PV layers. Proper recycling separates them cleanly so materials can be recovered and handled correctly.

Frames and Mounting Hardware

Some thin-film panels come with aluminum frames, while others are frameless. Either way, you’ll also have fasteners, clamps, rails, and adhesives from the mounting system.

These materials can add weight and change how pallets are built, loaded, and shipped—especially on large decommissioning jobs.

How Thin-Film Panels Are Manufactured

Thin-film panels are made by depositing ultra-thin photovoltaic materials onto a substrate (like glass, metal, or plastic), then laminating and sealing the stack so it can survive outdoors.

This matters because the manufacturing method influences:

- Layer thickness: tiny variations affect performance and durability.

- Material purity: Cleaner deposition can improve consistency and output.

- Recycling complexity: bonded layers and encapsulants can make separation more involved than people expect.

Why Material Composition Matters for Recycling and Safety

Recycling Pathways Depend on the Chemistry

Thin-film recycling is not one-size-fits-all. CdTe, CIGS, and a-Si each come with different handling and recovery considerations, especially when you’re dealing with large volumes.

The practical takeaway: use a licensed electronics recycler who can manage downstream processing correctly and provide documentation that stands up to internal compliance requirements.

Handling and Storage Basics

Don’t treat solar modules like scrap metal.

- Do not cut, crush, or dismantle panels on-site.

- Keep modules intact, palletized, and protected (especially glass).

- Store them in a stable area and follow your recycler’s packaging and pickup guidance.

How to Identify What Your Thin-Film Panels Are Made Of

You don’t have to guess.

- Start with the manufacturer’s label and datasheet.

- Look for the model series and the technology type (often listed as CdTe, CIGS, or a-Si).

- For large projects, build a simple inventory:

- Count

- Condition

- Location

- Manufacturer

- Model

- Count

That inventory makes quotes cleaner, pickups faster, and compliance documentation easier.

FAQs

Are thin-film solar panels hazardous?

Not inherently. But certain thin-film types (especially CdTe) require responsible end-of-life recycling due to the materials involved. Treat them as industrial equipment—manage storage and recycling correctly.

Can thin-film panels be recycled the same way as crystalline panels?

Not always. Crystalline silicon panels and thin-film panels can follow different recovery pathways because the absorber materials and layer structures are different.

Does CdTe mean the panel is “dangerous” to store?

No—intact modules stored properly are not the same as loose raw materials. The risk increases when panels are broken, crushed, or improperly processed, which is why qualified recycling matters.

What documentation should businesses request after recycling?

At minimum, request documentation that supports compliance and internal reporting—typically a certificate of recycling.

Conclusion

Thin-film solar panels are built as a layered stack: substrate + conductive layers + thin absorber + encapsulation. Once you understand that structure, the end-of-life process makes more sense—because recycling and handling depend heavily on what those layers are made of.

When thin-film modules reach the end of life, EACR Inc. can coordinate solar panel recycling and provide the documentation your facility needs for compliant disposal.