The answer to what solar panels are made of is simple: they’re primarily built from silicon solar cells, a protective glass layer, an aluminum frame, wiring, and encapsulation materials. Each part plays a crucial role in making solar panels durable, efficient, and able to generate clean electricity for decades.

Understanding solar panel materials matters because they directly affect efficiency, cost, and sustainability. The type of silicon used can determine how much energy a panel produces, while the frame and protective layers influence how long the panel lasts on a rooftop.

By breaking down these components, we can see not only how solar panels work but also how their materials shape their environmental impact—from manufacturing through recycling. EACR Inc is a licensed electronics recycling company that can recycle all aspects of solar panels.

Core Materials in Solar Panels

Solar panels might look simple from the outside, but each one is made of carefully engineered layers that work together to capture and convert sunlight into electricity.

Silicon Solar Cells

At the heart of every panel are silicon solar cells, which create electricity through the photovoltaic effect. When sunlight hits these cells, electrons move, generating a current that powers your home.

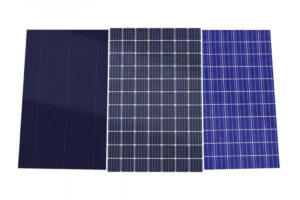

There are three main types:

- Monocrystalline: Made from a single silicon crystal, offering the highest efficiency and sleek black look.

- Polycrystalline: Made from multiple silicon crystals, slightly less efficient but more affordable, with a bluish hue.

- Thin-Film: Made from alternative materials like cadmium telluride or amorphous silicon, lightweight and flexible but less efficient.

Silicon dominates the solar industry because it’s abundant, reliable, and strikes the best balance between cost and performance.

Glass Layer

On top of the solar cells sits a glass sheet that protects them while still allowing sunlight to pass through. This layer is typically 6–7 millimeters thick—thin enough to let in light but strong enough to withstand hail, wind, and daily weather.

Beyond protection, the glass helps regulate heat. By reducing overheating, it keeps solar cells working efficiently even under intense sun exposure.

Aluminum Frame

Holding everything together is the aluminum frame, which provides structure and support. Aluminum is ideal because it’s lightweight, corrosion-resistant, and recyclable.

The frame ensures the panel stays secure on your roof or ground mount and makes installation easier. Without it, solar panels would be fragile and harder to handle.

Encapsulation and Back Sheet

Inside the panel, encapsulation layers surround the silicon cells, sealing them from moisture, dirt, and mechanical stress.

On the underside, the back sheet acts as insulation, protecting the cells and wiring from humidity and UV radiation. Together, these layers are critical for panel efficiency and long lifespan, often 25 years or more.

Wiring and Bus Bars

Finally, the electricity produced by solar cells needs a pathway out of the panel. This is where wiring and bus bars come in. Typically made of copper or silver, these conductors transfer the electric current with minimal loss.

The junction box, located on the back of the panel, ensures electricity flows in one direction only—preventing reverse current that could damage the system.

How Solar Panels Are Made

The answer to what solar panels are made of isn’t complete without understanding how they’re manufactured. The process takes raw sand and transforms it into high-performing solar modules that can power homes for decades.

From Sand to Silicon Wafers

Solar panels start with silicon dioxide, found in sand. Through purification and crystallization, it’s converted into high-purity silicon ingots. These solid blocks form the base material for solar cells.

Cutting and Doping Wafers

The ingots are sliced into thin silicon wafers. To make them conductive, they’re “doped” with boron and phosphorus, creating positive and negative charges that allow electrons to flow. An anti-reflective coating is then added to maximize sunlight absorption.

Assembling the Panel

Once the wafers become cells, they’re soldered together in a grid-like pattern. Layers of glass, encapsulant, and a back sheet are added for protection. An aluminum frame completes the structure, making the panel durable and ready for installation.

Quality Testing

Before leaving the factory, panels undergo Standard Test Conditions (STC) checks, simulating sunlight and temperature. Only panels that meet efficiency and safety benchmarks make it to the market.

Types of Solar Panels by Materials

Not all solar panels are built the same. The materials used in their construction impact efficiency, durability, and cost.

Monocrystalline Panels

- Made from a single-crystal silicon structure.

- Known for the highest efficiency rates and sleek black finish.

- More expensive due to the intensive manufacturing process.

Polycrystalline Panels

- Made by melting multiple silicon crystals together.

- Slightly lower efficiency but more affordable.

- Recognizable by their bluish, speckled appearance.

Thin-Film Panels

- Made from materials like amorphous silicon, cadmium telluride, or CIGS.

- Lightweight, flexible, and easy to install in unconventional spaces.

- Less efficient than crystalline panels, but useful in niche applications.

Final Thoughts: What Are Solar Panels Made of?

So, what are solar panels made of? At their core: silicon solar cells, protective glass, aluminum frames, wiring, and encapsulation layers. Each material plays a role in durability, efficiency, and sustainability.

As clean energy becomes mainstream, it’s important to remember that materials matter. High-quality components lead to better performance, longer lifespans, and less environmental waste.

When choosing solar panels, look for trusted manufacturers, prioritize durability, and keep in mind the importance of solar panel recycling when panels reach the end of their life. It’s the smartest way to make solar both powerful and sustainable.