Solar farm decommissioning is becoming an increasingly important part of the renewable energy conversation. As solar energy continues to expand worldwide, many early-generation solar farms are reaching the end of their life cycles. These large-scale systems—once symbols of progress—now need responsible plans for what happens next.

Decommissioning isn’t just about taking down old solar panels. It also involves inverters, racking systems, wiring, batteries, and concrete foundations — all of which require proper handling and recycling. Every part of a solar system can be processed to recover recyclable materials like aluminum, copper, steel, and silicon, helping minimize waste and environmental impact.

Sustainable decommissioning ensures solar sites are prepared for reuse or repowering, keeping land productive and maintaining solar’s clean-energy promise. From dismantling to recycling and site restoration, the process is about closing the loop on renewable energy.

EACR Inc. supports solar farm owners, developers, and EPC firms with full-scale recycling and decommissioning services that manage every component — panels, inverters, and supporting infrastructure — from start to finish.

EACR Inc. helps solar developers, EPC firms, and utility providers responsibly recycle panels, inverters, and full system components through our solar panel recycling program.

What Does Solar Farm Decommissioning Involve?

Step 1: Site Assessment

The process begins with a detailed site assessment to evaluate the condition of panels, inverters, and structural components. This step helps determine which materials can be reused, or recycled. Assessments also identify potential environmental risks, like wiring contamination or foundation issues, ensuring the decommissioning plan meets regulatory standards before removal begins.

Step 2: Disassembly & Removal

Once the site plan is complete, teams carefully disassemble solar modules, racking systems, and wiring. Each component is removed with attention to preserving materials for recycling and reuse. Inverters, transformers, and control systems require special handling to prevent damage or environmental harm. This step ensures every piece of the system is safely extracted without disrupting the surrounding land or utility connections.

Step 3: Recycling & Material Recovery

After disassembly, materials are sorted and separated for recycling. Components such as glass, aluminum, copper, silicon, and steel are processed for reuse, while any non-recyclable parts are disposed of responsibly under applicable guidelines. This step reduces waste, conserves resources, and keeps recyclable materials circulating within the renewable energy industry.

Why Sustainable Decommissioning Matters

Avoiding Future Solar Waste

Solar farm decommissioning is more than a cleanup process — it’s an environmental responsibility. As more solar farms reach the end of their service life, unmanaged solar waste could lead to mounting environmental and regulatory challenges.

By focusing on recycling and proper material recovery, operators can prevent landfill buildup and maintain the long-term credibility of clean energy. Responsible decommissioning ensures that renewable energy stays renewable — not just in production, but through every stage of its lifecycle.

Recovering Recyclable Materials

Solar farms are full of recyclable materials waiting to be recovered. Solar panels and inverters contain components such as aluminum, copper, silicon, and steel, all of which can be reclaimed and reintroduced into manufacturing.

Recovering these materials reduces the need for new mining and extraction while keeping reusable resources circulating within the renewable energy supply chain. This approach helps extend the life of materials already in use and reduces overall waste generation.

Reducing Costs and Carbon Impact

Sustainable decommissioning isn’t just good for the environment — it’s cost-effective, too. Responsible recycling helps reduce waste-handling expenses, minimizes transportation costs for disposal, and avoids potential environmental fines. By reusing metals and materials already in circulation, solar farm operators can lower their carbon footprint and reduce the emissions associated with new material production and mining. It’s a practical, financially sound way to keep sustainability at the forefront of solar energy’s future.

Components That Require Responsible Recycling

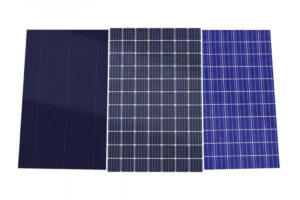

Solar Panels

Solar panels are made up of glass, aluminum, and trace elements like copper and silicon, which can all be recycled through specialized recovery processes instead of discarding old panels. Proper recycling allows these materials to be separated, cleaned, and used again in new solar products or other manufacturing industries.

Solar Inverters

Solar inverters contain recyclable metals and electronic parts that should never enter landfills. Because inverters are typically replaced more frequently than panels, they create a consistent stream of recyclable material. Proper inverter recycling ensures metals and circuit components are recovered safely, supporting long-term sustainability goals for the solar industry.

Mounting Structures and Racking

The framework that supports a solar farm — including steel and aluminum racking systems — can be dismantled and recycled easily. Reprocessing these metals for new construction or manufacturing significantly reduces waste and raw material consumption.

Electrical Wiring and Cabling

Solar farms contain extensive networks of copper wiring and insulated cabling. These materials can be safely processed to separate the copper for reuse and recycle or responsibly dispose of the plastic coatings. Copper recovery, in particular, is one of the most efficient ways to reduce the environmental footprint of solar system decommissioning.

Batteries and Storage Systems

Energy storage systems, including lithium, nickel, and cobalt-based batteries, require specialized recycling processes to prevent contamination and ensure proper recovery. When handled responsibly, these materials can be reintroduced into battery manufacturing or other industries, helping close the loop on energy storage sustainability.

Challenges in Large-Scale Solar Decommissioning

Solar farm decommissioning on a large scale comes with unique challenges that go beyond simple removal or recycling. The biggest hurdle is the lack of standardized regulations across states and countries. With no universal framework, developers often face different recycling rules and disposal requirements depending on location. This inconsistency slows down projects and increases costs.

Another major challenge is the high logistics cost of transporting large, heavy materials such as panels, steel racking, and transformers. Solar farms can cover hundreds of acres, so moving equipment safely and efficiently requires significant planning and expense.

There’s also inconsistent recycling infrastructure for specialized components like inverters, batteries, and wiring. While panel recycling is growing rapidly, other parts of the system often get overlooked. The industry needs more licensed recyclers capable of handling full-system processing — not just panels — to ensure all recyclable materials are recovered responsibly.

The Path Forward: Building a Circular Solar Economy

The future of solar farm decommissioning lies in adopting a true circular economy approach. Full-system recycling — including panels, inverters, wiring, and metals — ensures materials stay in use rather than being discarded. Every recovered component helps reduce the demand for raw materials and supports cleaner manufacturing practices.

Manufacturers and developers can play a major role by integrating end-of-life planning at the design stage. Building solar components that are easier to disassemble and recycle will help streamline future decommissioning efforts.

Sustainability also depends on collaboration. Partnerships between recyclers, developers, and policymakers are key to creating infrastructure that can manage the full lifecycle of solar systems efficiently and responsibly.

Partner with EACR Inc. to handle solar farm decommissioning the right way — from inverter recovery to full material processing.

Final Thoughts

The solar industry’s next big challenge isn’t adoption — it’s sustainability. As more solar farms reach the end of their lifespan, responsible solar farm decommissioning will determine how truly renewable this energy source remains.

Sustainable decommissioning ensures solar energy continues to deliver environmental benefits for decades to come. By recovering recyclable materials, restoring land responsibly, and reducing waste, the industry can close the loop on clean energy.

Project owners, developers, and municipalities can make the greatest impact by working with a licensed solar panel recycler like EACR Inc. — ensuring every solar system ends its life as cleanly as it began.