Forklift batteries power warehouses, distribution centers, and industrial operations every day. Without them, material handling comes to a stop.

But these batteries also contain hazardous materials that can cause serious problems when they’re mishandled or disposed of incorrectly. Improper handling creates environmental damage, fire hazards, and legal exposure for businesses.

This guide breaks down:

- What forklift batteries are made of

- Why recycling is required, not optional

- How the recycling process works

- How businesses can recycle safely and stay compliant

What is a Forklift Battery?

A forklift battery is a large industrial power source designed to run heavy equipment for long shifts. Unlike consumer batteries, these are built for high load, repeated charging, and long operational life.

Forklift batteries are much larger, heavier, and more chemically complex than automotive or household batteries. Because of their size and material content, they are classified as industrial electronic waste and must be handled through licensed recycling programs.

Types of Forklift Batteries That Require Recycling

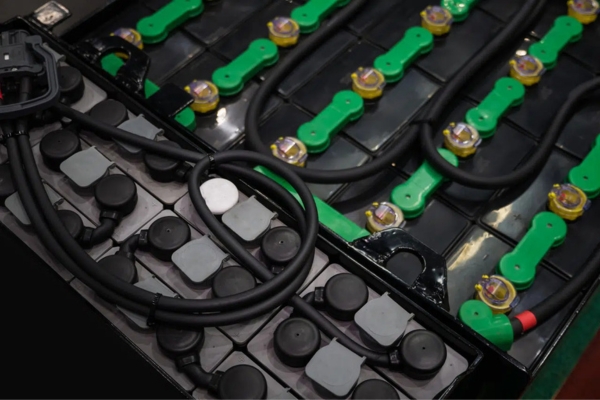

Lead-Acid Forklift Batteries

Lead-acid batteries are the most common battery type used in material handling equipment today. They are reliable, powerful, and widely available.

These batteries contain lead plates, sulfuric acid, and heavy plastic casings. While they are highly recyclable, they are also dangerous if damaged, leaked, or improperly stored. Acid spills and lead exposure pose serious environmental and safety risks.

Lithium-Ion Forklift Batteries

Lithium-ion forklift batteries are becoming more common in newer fleets due to their lighter weight and longer lifespan. They offer higher energy density and faster charging compared to lead-acid systems.

However, lithium-ion batteries require specialized handling. If punctured, crushed, or improperly transported, they can overheat or ignite, making controlled recycling essential.

Other Industrial Battery Systems

In addition to standard forklift batteries, many facilities also use:

- Pallet jack batteries

- Industrial power packs

- Specialty batteries used in warehouse and logistics equipment

These systems are also regulated and must be recycled through proper industrial battery programs.

Why Forklift Batteries Should Never Be Thrown Away

Environmental Risks

Forklift batteries contain materials that can severely contaminate the environment. Lead and battery acid can leak into soil and groundwater, causing long-term pollution that is difficult and expensive to remediate.

Once released, these contaminants can harm ecosystems, wildlife, and nearby communities.

Fire and Safety Hazards

Forklift batteries pose serious fire and safety risks when mishandled. Short circuits, damaged casings, or improper storage can lead to dangerous reactions.

Lithium-ion batteries, in particular, carry a high fire risk if crushed or exposed to heat. Improper disposal also increases safety concerns during transportation and at waste facilities.

Legal and Compliance Risks

Forklift battery disposal is regulated at both the federal and state levels. Businesses are responsible for ensuring batteries are recycled properly from the moment they are removed from service.

Improper disposal can result in fines, penalties, and long-term liability. Working with a licensed recycler protects your organization and ensures compliance with environmental regulations.

Is Forklift Battery Recycling Required by Law?

Forklift battery recycling isn’t optional—it’s required. In the U.S., rechargeable industrial batteries are regulated under the Mercury-Containing and Rechargeable Battery Management Act.

These regulations place responsibility on the generator (the business that owns the battery) from removal through final recycling. That’s known as cradle-to-grave liability. If a battery is mishandled downstream, the original owner can still be held accountable.

This is why documentation matters. Recycling records and certificates prove batteries were handled properly.

The Forklift Battery Recycling Process

1. Collection and Transportation

The process starts with a safe, planned collection. Forklift batteries are picked up on a scheduled basis, often in bulk, using equipment designed for heavy industrial loads.

Secure transport is critical. Batteries are packaged and moved in a way that prevents tipping, short-circuiting, or leaks during transit.

2. Sorting

Once received, each battery is identified by chemistry—lead-acid, lithium-ion, or other industrial types. Condition checks are performed to flag damaged or leaking units.

This step ensures the right processing method is used and prevents safety issues during handling.

3. Disassembly and Processing

Batteries are processed in controlled environments. Lead, plastic casings, acids, or lithium cells are separated using approved methods.

Safety controls are in place throughout this stage to protect workers and prevent environmental release.

4. Responsible Material Recovery

Recovered materials are routed properly:

- Metals are reclaimed for reuse

- Plastics are processed for recycling

- Electrolytes are neutralized and treated

Nothing recyclable is sent to a landfill. This zero-landfill approach is what separates licensed recycling from disposal.

How to Prepare Forklift Batteries for Recycling

Preparing batteries correctly reduces risk before pickup.

Cover or tape exposed terminals to prevent short circuits. Store batteries upright in a secure area away from heat or traffic until collection.

Do not drain acid, dismantle batteries, or stack them in unstable piles. Improper handling increases safety risks and can delay pickup.

What Happens to Forklift Batteries After Recycling?

Recovered lead is refined and reused in new batteries and industrial products. Plastics are cleaned and reprocessed into new materials.

Lithium-based batteries are handled through specialized downstream channels designed to safely recover metals and manage fire risk.

Material recovery reduces the need for new mining, lowers energy use, and keeps hazardous materials out of the environment.

Forklift Battery Recycling for Businesses

Warehouses & Distribution Centers

Facilities managing forklift fleets often replace batteries in phases. Ongoing recycling programs make it easy to handle battery changeouts without disruption.

Manufacturing & Industrial Facilities

High-volume operations benefit from structured battery management plans. Recycling documentation supports environmental compliance and internal reporting.

Municipal & Government Operations

Public agencies must meet strict safety and environmental standards. Audit-ready recycling records ensure transparency and accountability.

Forklift Battery Recycling vs. Disposal or Scrap

Scrap yards focus on metal value—not safety, compliance, or environmental protection. Most cannot legally handle acids, lithium cells, or regulated battery components.

Informal disposal increases fire risk and leaves liability with the generator. Recycling, by contrast, ensures full system processing under licensed controls.

Licensed recyclers handle the entire battery—not just the parts worth money.

Why Work With a Licensed Forklift Battery Recycler

Licensed recyclers ensure compliance with all applicable regulations while protecting workers, facilities, and the environment.

They reduce fire risk, manage hazardous materials correctly, and provide certificates of recycling for your records.

Conclusion: Recycle Forklift Batteries the Right Way

Forklift batteries are not ordinary waste. They are regulated industrial equipment that requires proper handling at the end of life.

Recycling protects people, facilities, and the environment while keeping your business compliant. Licensed recycling ensures materials are recovered safely and responsibly. Contact EACR Inc. today to schedule forklift battery recycling and ensure your batteries are handled the right way from pickup to final processing.