Aluminum heatsink recycling is straightforward when you treat heat sinks like a metal stream with rules, not random waste. Heat sinks are the metal cooling blocks you see everywhere—PCs and servers, LED lighting, telecom gear, automotive electronics, and power supplies.

Recycling matters because aluminum is one of the most recyclable materials we use—and recycled aluminum takes dramatically less energy than making new aluminum from ore. Translation: if you keep heat sinks clean and in the right channel, you cut waste and reduce the footprint behind replacement parts.

In this guide, you’ll learn how to identify what you actually have (pure aluminum vs mixed-metal), how to prep it without wasting time, and how to route heat sinks correctly—whether they’re loose, still mounted to hardware, or mixed into a larger electronics load.

What is an Aluminum Heat Sink?

Plain-English definition

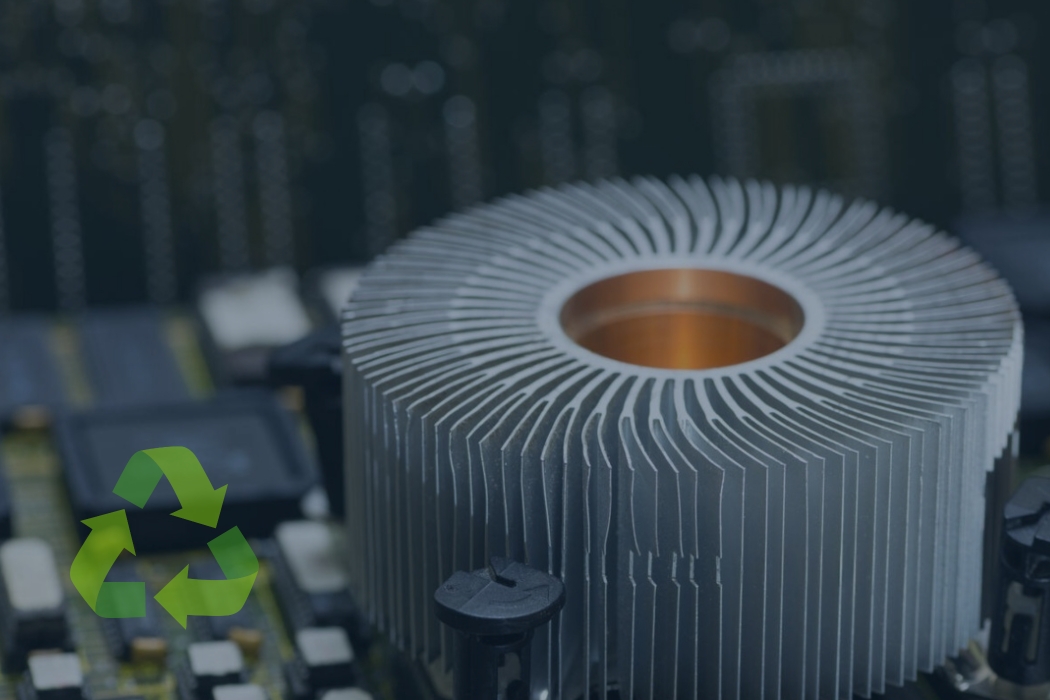

An aluminum heat sink is a metal part designed to pull heat away from electronics and dump it into the air. It does that with surface area—those fins or pins aren’t decoration, they’re the whole point.

Why aluminum is common

Aluminum hits the sweet spot: it moves heat well, it’s lightweight, and it’s easy to extrude or machine into finned shapes. That’s why you see aluminum heat sinks everywhere, from laptops to LED fixtures to industrial power equipment.

How Heat Sinks Work (fast + useful)

Conduction, convection, radiation (in one minute)

- Conduction: heat moves from the hot component (CPU/driver/power transistor) into the heat sink base through direct contact.

- Convection: fins or pins increase surface area so airflow can carry that heat away. Fans help, but even passive heat sinks rely on air movement.

- Radiation: the surface also sheds a smaller portion of heat as infrared energy—usually not the main mechanism, but it contributes.

Why Recycling Aluminum Heat Sinks Matters

Sustainability win: recycled aluminum vs virgin aluminum

According to Aluminum.org, recycled aluminum saves 95% of the energy needed to make new aluminum. from raw materials. For businesses, that becomes a practical sustainability lever: lower embodied energy, better material recovery, and cleaner reporting when you can show metal streams are being captured instead of trashed.

The circular loop in real manufacturing

Heat sink production creates scrap—chips, shavings (swarf), offcuts. Done right, that material gets collected, re-melted, and re-used as feedstock. That’s what a “circular economy” looks like in real life: not magic, just clean sorting and repeatable routing.

Heat Sink Types You’ll See in the Waste Stream

Finned (extruded) heat sinks

The most common type: thick base with fins. Found in PCs, power supplies, telecom equipment, industrial controls—basically anything that runs hot.

Pin heat sinks

Instead of fins, you’ll see an array of pins. These often show up in compact devices or applications with airflow coming from different directions—common in LEDs and tight enclosures.

Stacked / bonded / skived

Higher-performance designs that combine layers, bonded fins, or “skived” fins cut from a single block. More complex construction can mean more mixed materials and more attachments.

Liquid-cooled assemblies (callout)

These are not “just aluminum.” You may have copper cold plates, fittings, hoses, pumps, or coolant residue. Treat liquid-cooled parts as assemblies that need a different route than clean aluminum heat sinks.

What Makes Heat Sink Recycling Tricky

Mixed metals

A lot of heat sinks look like aluminum but aren’t “clean aluminum.”

- Aluminum bases with copper heat pipes or copper inserts

- Steel fasteners, brackets, springs, clips

Mixed metal doesn’t make recycling impossible—it just changes the best route and the expected value/recovery.

Contamination and attachments

This is the stuff that turns an easy metal stream into a messy one:

- Thermal paste, pads, adhesives

- Heat sinks still mounted to PCBs, fan shrouds, housings, or full devices

If it’s attached to electronics, you’re often better off routing it through an electronics/ITAD program unless you’re set up to separate components safely.

Painted/anodized surfaces

Painted or anodized heat sinks are usually still recyclable, but finishes and coatings can affect downstream sorting. The key is consistency: keep like-with-like when you can.

How to Prepare Aluminum Heat Sinks for Recycling

Step 1: Identify what you have (don’t guess)

Start with a simple classification: aluminum, copper, or mixed assembly. Quick checks that actually work:

- Magnet test: if it grabs hard, you’ve got steel in the mix (brackets/screws/frames).

- Weight + color: copper is heavier and more reddish; aluminum is lighter and silver-gray.

- Part design: heat pipes, plates, or embedded tubes usually mean mixed metals.

If you can’t confidently separate it, treat it as an assembly and route it accordingly.

Step 2: Separate the easy stuff

Don’t turn this into a labor project. Just pull the obvious wins:

- Remove easy steel brackets/screws/clips when practical

- Keep heat sinks separate from loose cables and “small mixed bits” so they don’t get lost or downgraded

- If heat sinks are still attached to boards or fans, keep that group together as a single stream (don’t half-dismantle and create mess)

Step 3: Stage and package for safe transport

Heat sinks are heavy and can be sharp.

- Use bins/totes/boxes that can handle weight and don’t split

- Don’t let fins turn into “metal shrapnel” in a gaylord—contain them

- Never mix with loose batteries. That’s how avoidable incidents happen (crushing + shorts)

Recycling Routes

Option 1: Drop-off

Best for households and low volume: a few loose heat sinks or a small box of parts. Confirm acceptance rules if the location expects devices, not components.

Option 2: Electronics recycling partner

Working with an electronics recycling company is best when heat sinks are still attached to servers, PCs, power supplies, LED fixtures, or network gear. This route is built for:

- proper disassembly

- consistent downstream routing

- documentation (especially useful for audits/vendor oversight)

Option 3: E-waste container service

Best for businesses, schools, and municipalities that want a simple, repeatable route. EACR Inc. can place an e-waste container on-site, so heat sinks can go out as part of your normal electronics stream—no scrambling for last-minute drop-offs or “where do we take this?” decisions.

Why this works:

- Easy staging: collect parts in one controlled spot instead of piling loose metal around a shop or IT room

- Quick offload: when you’re ready, it’s a straightforward drop-off or scheduled movement—especially helpful for cleanouts and ongoing maintenance scrap

- Cleaner routing: keeps heat sinks with related electronics (and away from batteries/incident risks)

- Operationally simple: a good fit for facilities that generate parts in waves (IT refreshes, LED retrofits, telecom swaps)

What Happens After Collection (high level)

Sorting + separation

Once heat sinks arrive at a recycler, they’re treated like a metal recovery stream, not “random electronics.”

- Aluminum gets separated from copper-heavy parts (like heat pipes) and steel (brackets, screws, springs).

- Loads are screened for “problem add-ons” (boards, batteries, fan assemblies, plastics).

- Contamination is reduced where practical so the aluminum stream stays clean enough to process efficiently.

Processing + re-melt

Clean aluminum heat sinks are routed into a re-melt pathway—meaning the material is processed and melted down so it can re-enter manufacturing streams as recycled aluminum feedstock. The more consistent and uncontaminated the stream, the better the downstream outcome.

Common Mistakes

- Throwing heat sinks into mixed e-waste with batteries (this is how avoidable incidents start)

- Not separating mixed-metal assemblies when it’s easy (steel brackets + copper heat pipes drag down the whole load)

- Letting thermal paste and attachments turn “clean aluminum” into a messy load (boards, housings, fans, adhesive pads = downgrade + extra handling)

FAQs on Aluminum Heatsink Recycling

Are aluminum heat sinks recyclable?

Yes. Aluminum heat sinks are recyclable when they’re routed as a metal stream or through a proper electronics recycling program—especially when they’re part of larger devices.

Are heat sinks aluminum or copper?

Many are aluminum, but mixed builds are common (aluminum with copper heat pipes/inserts) plus steel fasteners. If you see copper tubes or embedded plates, treat it as a mixed-metal assembly.

Do I need to remove thermal paste?

Not usually. Light residue is typically fine. The bigger issue is leaving heat sinks attached to boards, fans, housings, or adhesive pads that turn a clean metal stream into a mixed load.

Can I recycle heat sinks still attached to a motherboard?

Yes—but route it as electronics, not scrap metal. Keeping assemblies intact is often safer and cleaner than partial DIY teardown.

Can businesses get documentation for recycling?

Yes. Businesses can typically request service records and recycling documentation, which helps with audits, vendor management, and sustainability reporting.

Conclusion: Keep aluminum in the loop

Identify what you have, separate what’s easy, and route heat sinks through the right channel so aluminum stays in circulation instead of getting downgraded or trashed.

If you’re processing heat sinks from PCs, servers, LEDs, telecom gear, or mixed electronics loads, EACR Inc. can handle them through an electronics recycling program with controlled downstream routing and documentation.